- Home

- Company Profile

- Our Poducts

- APPLICATIONS

- Contact Us

Brass Spacer

A brass spacer is a cylindrical component made of brass that is used to create space or separation between two objects in an assembly. These spacers are designed to provide support, alignment, and proper spacing between components. They come in various shapes and sizes, and their applications can range from electronic and mechanical assemblies to industrial and automotive contexts.

Price upon request

Knurled Brass Insert

A knurled brass insert is a type of fastener used in various applications to create a threaded or reinforced hole in a softer material, typically plastic or wood. The knurled design provides enhanced grip and allows for easy installation into the host material. These inserts are often used in industries such as electronics, furniture manufacturing, and automotive applications.

Price upon request

Threaded Hex Nut

A Threaded Hex Nut is a six-sided fastener with internal threads that allow it to be screwed onto a corresponding bolt or threaded rod. Hex nuts are one of the most common types of fasteners used across a wide range of applications, from construction and automotive to industrial machinery. Made from materials like steel, stainless steel, or brass, they offer high strength and durability. The hexagonal shape provides an optimal grip for wrenches, enabling easy tightening or loosening, which ensures secure and reliable fastening in assemblies.

Price upon request

Threaded Square Nut

A Threaded Square Nut is a type of fastener with a square-shaped body and internal threading, designed to mate with a corresponding bolt or threaded rod. The square shape provides a larger surface area for wrenching, making it easier to apply torque and secure the nut in place. Commonly used in construction, machinery, and automotive applications, threaded square nuts are made from materials like steel, brass, or stainless steel, ensuring strength and durability. Their design allows for a more stable and secure fastening solution, particularly in heavy-duty applications.

Price upon request

Brass Ring

Brass Rings are precision-engineered components used in a variety of applications, including mechanical assemblies and plumbing systems. Crafted from high-quality brass, these rings offer excellent durability, corrosion resistance, and a tight seal to prevent leaks. Their robust construction ensures reliability and longevity, making them ideal for use in both industrial and residential applications where strength and resistance to wear are essential.

Price upon request

Turned Part

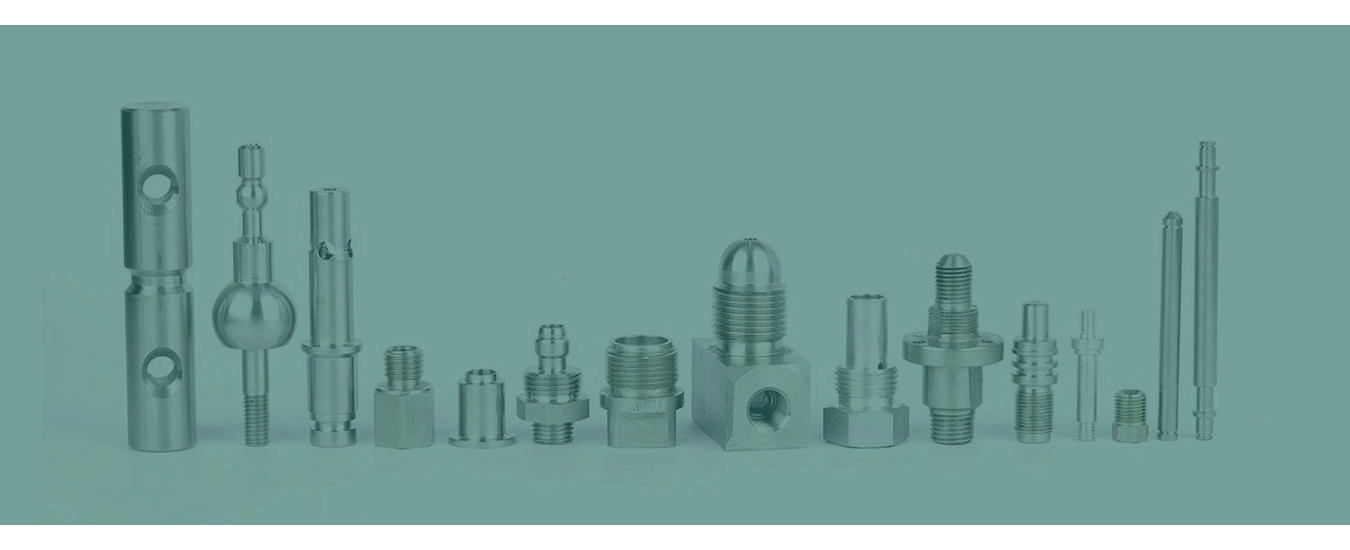

Turned Parts refer to components that are shaped using a lathe or similar turning machine, where material is rotated and cut to create specific geometries. These parts can range from simple cylindrical shapes to complex designs, depending on the requirements. Common materials used include metals like brass, aluminum, and stainless steel. Turned parts are widely used in industries such as automotive, aerospace, and electronics for applications that demand precision, durability, and consistency in performance.

Price upon request

Threaded Bush

A threaded bushing, often simply referred to as a threaded bush, is a type of fastener or connector used to join two or more components. It typically consists of a cylindrical metal or plastic piece with internal threads that match the external threads of a corresponding screw, bolt, or rod. The primary purpose of a threaded bush is to provide a secure and threaded connection between components.

Price upon request

Turned Bush

A Turned Bush is a type of bearing or spacer that has been machined through the turning process to achieve precise dimensions and surface finish. Made from materials like brass, bronze, or steel, turned bushes are used to reduce friction and wear between moving parts, typically in machinery or automotive applications. The precision turning process ensures that these bushes fit accurately within assemblies, contributing to the smooth operation and longevity of mechanical systems.

Price upon request

Brass Slotted Tube

A brass slotted tube is a hollow cylindrical component crafted from high-quality brass, characterized by its distinctive slots or openings along its length. These slots are designed in various patterns and sizes, tailored to meet specific application and functional needs. The versatility of brass slotted tubes makes them suitable for a broad range of industries, including automotive, aerospace, and construction.

They are often used for applications such as ventilation, filtration, and structural reinforcement, where both strength and precision are required. The brass material offers excellent durability, corrosion resistance, and a polished appearance, making these tubes ideal for both functional and aesthetic purposes.

Price upon request

Valves

Valves are essential components in fluid control systems, designed to regulate, direct, or control the flow of liquids, gases, or slurries. Available in various types such as ball, butterfly, gate, and solenoid valves, they are used across multiple industries including plumbing, oil and gas, HVAC, and manufacturing. Valves are typically made from robust materials like brass, stainless steel, or PVC to withstand different pressures and environmental conditions. Their reliable operation ensures efficient system performance, safety, and longevity in both residential and industrial applications.

Price upon request

Hex Bush

A hex bush, also known as a hexagonal bushing, is a type of fitting used in plumbing and piping systems to connect pipes of different sizes. It is designed with a hexagonal (six-sided) shape for easy installation and removal using a wrench. Hex bushings have internal and external threads, allowing them to fit into a larger threaded opening on one side and connect to a smaller threaded pipe on the other side.

Price upon request

Brass Square Nut

A brass square nut is a type of fastener made from brass that has a square shape rather than the more common hexagonal shape found in standard nuts. These nuts are designed to be used with square bolts or threaded rods and provide a secure and stable connection. Brass square nuts are often chosen for their corrosion resistance, durability, and aesthetic appeal.

Price upon request

Threaded Turned

Threaded Turned Parts are components that have been machined using a turning process and then threaded to allow for secure fastening in assemblies. These parts are commonly used in applications where a strong and precise connection is required, such as in piping, automotive components, and machinery. Made from durable materials like steel or brass, threaded turned parts are designed to meet specific industry standards, ensuring reliability and ease of assembly in various mechanical systems.

Price upon request

Valve Stem

A Valve Stem is a critical component of a valve, acting as the link between the valve actuator and the valve disc or ball. It is responsible for transmitting the motion needed to open or close the valve, thereby controlling the flow of fluid. Typically made from stainless steel or other corrosion-resistant materials, valve stems are designed to withstand high pressures and temperatures. They are essential in ensuring the reliability and functionality of the valve, making them a vital part in applications ranging from automotive engines to industrial pipelines.

Price upon request

Turned Precision Part

Turned Precision Parts are custom-engineered components manufactured through the process of turning, where material is removed from a workpiece to achieve a precise shape and size. These parts are typically made from metals like brass, steel, or aluminum and are used in industries such as aerospace, automotive, and electronics. The high level of accuracy and quality in turned precision parts ensures their suitability for applications requiring tight tolerances and reliable performance. These components are often found in intricate machinery, where exact dimensions are crucial.

Price upon request